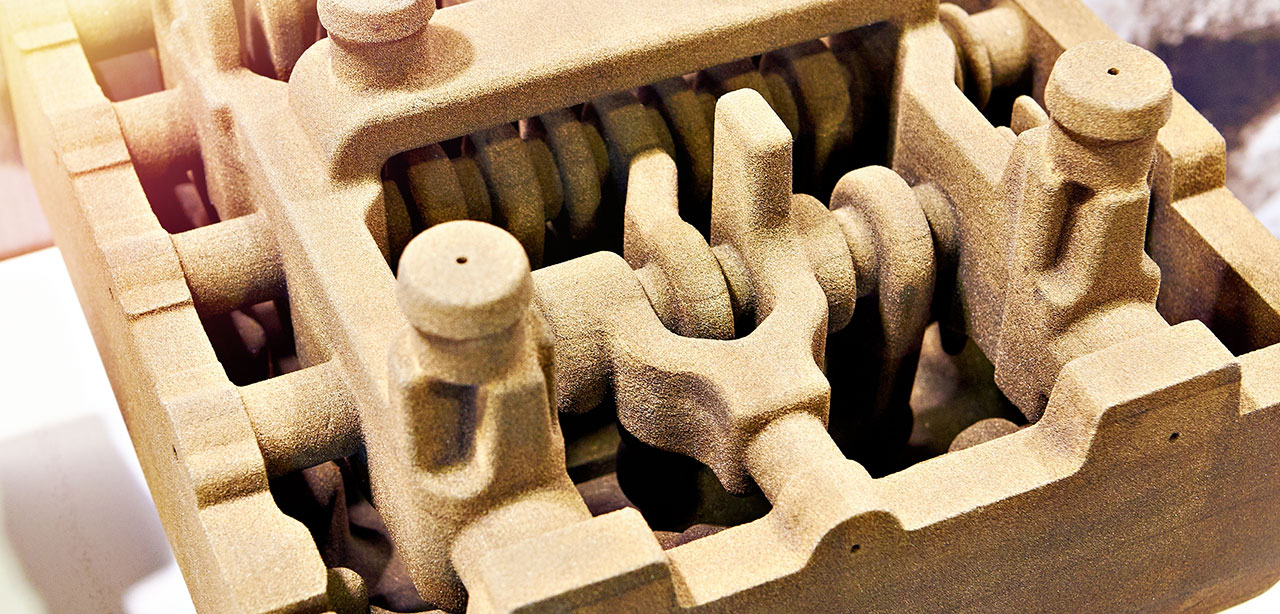

Steel Sand Casting with 3D-Printed Molds and Cores

Traditional mold-making methods often pose limitations in complexity, lead time, and cost. 3D-printed sand molds and cores are transforming the industry by offering unparalleled precision, design flexibility, and rapid production—ensuring that foundries can produce high-quality castings faster and more efficiently than ever before.

Why Choose 3D-Printed Sand Molds & Cores?

- Unmatched Design Freedom – Complex geometries, intricate internal structures, and optimized part designs can be achieved without the constraints of conventional core and mold-making techniques.

- Seamless Integration – 3D-printed molds and cores are fully compatible with existing foundry tools and processes, allowing for seamless integration while optimizing speed and design flexibility.

- Reduced Lead Times – Digital design and direct printing eliminate the need for tooling, drastically reducing turnaround time for new casting projects.

- Efficiency – Potential cost savings for prototyping, low-volume production and custom castings.

Get Started Today

Experience the future of steel casting using 3D-printed sand molds and cores. Whether you need rapid prototyping, complex part production, or a cost-effective solution for custom castings, we are here to help you redefine what’s possible in metal casting.

Contact us today to explore if 3D sand printing is the right fit for your casting project.

Request A Quote