Did you know the first foundry in what was to eventually become the United States, opened it’s doors in the year 1640? For almost 500 years, foundries have forged the backbone of American industry. Metal casting—turning molten metal into essential parts for cars, aircraft, and heavy machinery—is a symbol of strength and ingenuity. Today, however, that […]

Author Archives: Steve Shade

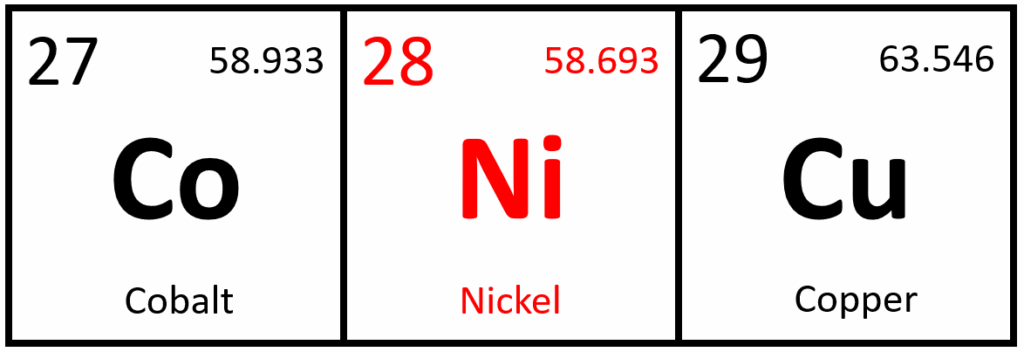

Nickel-based alloys such as Inconel and Hastelloy play a critical role where extreme performance is required. While carbon and stainless steels meet the needs of many applications, there are environments so demanding—so corrosive, hot, or high-stress—that only nickel-based alloys can provide reliable service. Why Nickel-Based Alloys? Nickel-based alloys combine exceptional corrosion resistance, heat resistance, and […]

Castings can, and likely do, contain porosity at least to some degree. What’s important to understand is how we can control the severity and location of the potential defect and the effect on the final part’s design and function. BackgroundPorosity is a natural—and sometimes unavoidable—aspect of the metal casting process. Tiny voids or gas pockets […]

At Minncast, we specialize in precision steel sand castings — but that’s just the beginning of the story. From concept to completion, we offer end-to-end manufacturing support that helps our customers bring complex metal components to life. Whether you’re in heavy industry, energy, defense, or transportation, here’s how Minncast adds value beyond the pour: Airset […]

In high-performance engineering environments, material selection is a critical decision that can significantly affect performance, longevity, and cost-effectiveness. One class of materials that has earned a reputation for reliability under extreme conditions is Ni-Resist cast iron. What is Ni-Resist?Ni-Resist is a family of austenitic cast irons alloyed primarily with nickel, along with other elements like […]

When you hear “casting,” it’s easy to think of a raw metal product priced simply by its weight. But the truth is, castings aren’t commodities. In fact, castings are no more of a commodity than machined, forged, fabricated, or injection molded components. They’re complex, engineered parts with unique manufacturing challenges that can’t be distilled down […]

As the severity and diversity of industrial processes increases, Severe Service Valves (SSVs) play an increasingly important role in isolating and controlling the various fluids used within them. Valves can be constructed with cast, wrought or forged components, but for cost efficiency, especially in large valves, castings are the most commonly used form of metal […]