Why Investing in Quality Tooling Is Essential for Sand Casting Success

Tooling is often treated as an upfront cost rather than a long-term investment. In sand casting, this mindset can be especially costly. While sand casting is known for flexibility and cost efficiency, the quality of the tooling behind the process directly determines consistency, yield, and overall profitability.

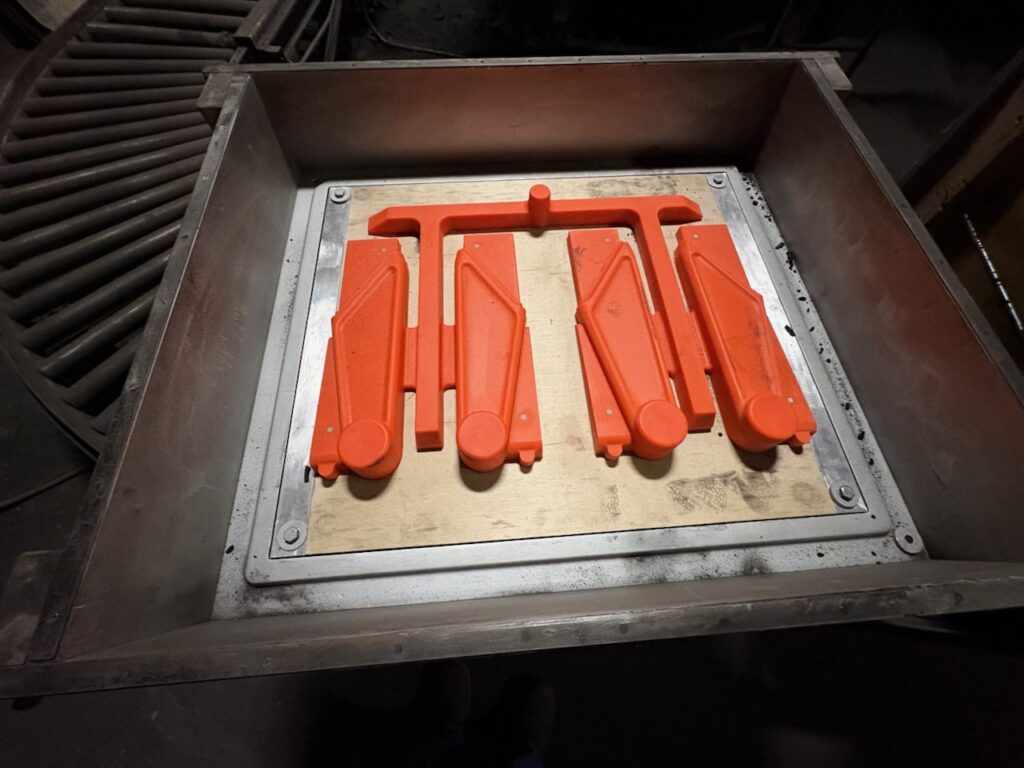

Tooling Is the Foundation of the Sand Casting Process

In the foundry, tooling defines part geometry, draft, core alignment, and gating design. Every mold produced reflects the condition and accuracy of the tooling used to make it. Poor tooling introduces variation that process controls alone cannot correct, leading to inconsistent castings and quality issues.

High-quality patterns and coreboxes deliver repeatability. Consistent molds improve metal flow, solidification, and dimensional accuracy—critical as customers demand tighter tolerances from sand cast components.

Lower Scrap and Reduced Rework

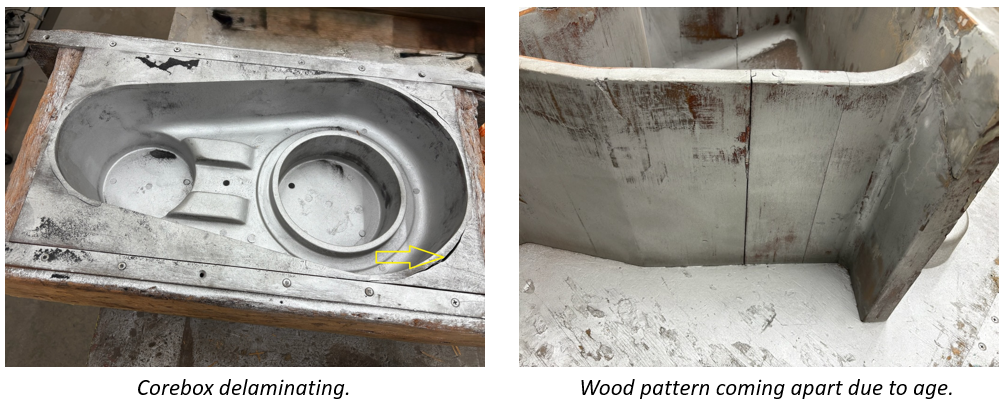

Inferior or worn out tooling is a common source of scrap, flash, mismatch, and excessive finishing. Each defect adds hidden costs in labor, material, and lost capacity. Rework such as grinding or welding consumes skilled labor and extends lead times.

Quality tooling reduces these issues by producing stable, accurate molds that perform consistently throughout production runs, improving yield and protecting margins.

Longer Tool Life and Better Economics

Foundry tools must endure repeated handling, compaction forces, and wear. Low-quality tooling often requires frequent repairs or replacement, quickly erasing any initial savings.

Well-designed tools last longer, requires less maintenance, and supports stable production. Over the life of a program, higher upfront tooling costs are typically offset by reduced downtime, fewer defects, and improved throughput.

A Strategic Manufacturing Investment

Tooling directly impacts cost, quality, delivery, and scalability. Manufacturers that invest in quality tooling gain greater process control, higher customer confidence, and a stronger competitive position.

It’s important to recognize that quality tooling is not an expense—it is a strategic asset that drives long-term manufacturing success.